Taking snapshots of the underground sounds like a pipe dream held by English club-goers or spelunkers. In geology, it’s done to understand the world beneath your feet.

The real world doesn’t wait for chance erosion to reveal sudden seams of value. Instead, after a careful topographic survey, one can use diamond coring to produce robust data.

Good data comes from good cores. And good cores come from expertise in procuring them without introducing contamination.

The following guide explains the purpose and process of diamond drilling for mineral exploration.

Diamond Coring Summary

Coring comes in two different varieties with slight differences in purpose and technique.

Using the right method is crucial to gathering useful cores and precise pictures of the mineralogy and material composition of an excavation site. The lithography of a site determines which technique is required.

Purpose

The purpose of exploration drilling is twofold. Comprehensive drilling services deliver better results when they understand target conditions and assess dangers.

Dangers include gross features that can sheer or buckle, ruining equipment and restricting access. Infiltrates that corrupt a resource and require purification or refining after extraction require attention. Looking out for the presence and amounts of these dangers leaves time and room to plan around them.

Careful core extraction yields more accurate results. Even newer machine-learning techniques can only do so much to repair muddied data sets.

Technique

As limiting contamination and damage to a core is paramount, diamond coring works to protect the core foremost.

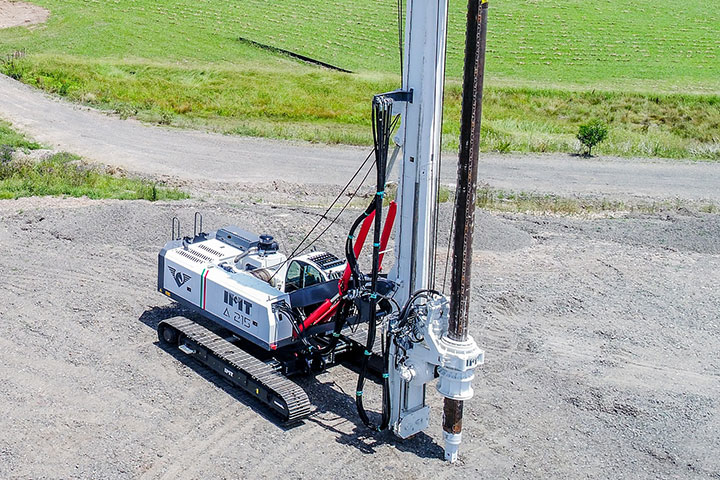

Building on the original use of diamond-tipped drills, coring rings a nested set of barrels with industrial-grade diamonds to break up and cut through hard and deep rock. Diamond coring enables telescoping samples up to 1500 meters.

Also referred to as diamond drilling, coring uses high-pressure pounding and twisting more than a singular spiral action. This crushes through the outer rock more efficiently while fluids keep the torsion from overheating the drilling rod.

Both soft and hard coring utilise nested barrels. In the hard coring of diamond coring, the outer barrel extends first. A solution of liquid or air pumps to separate the core from the outer barrel before it’s captured by the inner barrel.

The density of the rock keeps the fluids used in excavation from contaminating the samples overly.

Precautions

It’s necessary to take Cores from multiple locations to generate a comprehensive picture of the underlying strata. More cores mean more data but everything has diminishing returns.

Keeping the fluids balanced is an important component of the coring process. Too much or too little fluid affects core integrity before and after excavation.

This is why it’s important to work with drilling companies in Australia that know the local conditions and care about what’s being pumped and collected.

Hire Right

Engaging in diamond coring is a necessary step before investing in equipment placement or overcommitting to yield expectations. It’s far better to spend more on detailed surveyed than on retracting efforts and moving equipment.

Contact us with questions regarding the conditions of a site and we can provide more information about timetables.